DESCRIPTION

Plug and Play Turbocharger Upgrade for Mini Cooper Gen2 N14/N18 Engines

For our USA customers, all customs documentation is in order. The product is made in Canada and is tariff-exempt, except for the retaliatory tariff on metal. Shipping quotes will be DDP (Delivered Duty Paid), ensuring there are no surprise charges upon delivery.

R300 Turbocharger Features:

- Genuine Components: Built on a brand new OEM turbocharger as the core, ensuring superior quality and reliability.

- Quick Spool Performance: Engineered to replicate OEM spool characteristics, delivering consistent torque throughout the entire power band.

- OEM Catalytic Converter Compatibility: Designed to work with the OEM catalytic converter, allowing users to maintain emissions compliance.

- Optimized Compressor Wheel Design: Features a R300 Billet T6 2618 milled compressor wheel with a 6+6 blade design, engineered for optimal airflow and enhanced efficiency.

- Advanced Anti-Surge Technology: The compressor housing incorporates a patented built-in anti-surge and a ported shroud, significantly improving overall performance.

- High-Flow Turbine: Fitted with a genuine BorgWarner high-flow turbine, enhancing exhaust flow and overall engine efficiency.

- Enhanced Thrust Bearing: Utilizes an upgraded BorgWarner 360-degree thrust bearing package, ensuring increased durability and OEM-like lifespan.

- Balanced Assembly: Each unit is high-speed VSR balanced, ensuring superior operation and extending the turbocharger's lifespan.

- Power Capability: Tuneable from 260 WHP up to 300 WHP, depending on engine configuration, fuel type, and fuel system capabilities (MPI, W/M).

- True OEM Replacement: Engineered to meet or exceed OEM specifications, providing a direct replacement solution for seamless integration.

Manufactured and Engineered in Canada

Purchase Options:

- R300 Turbocharger only

- R300 Turbocharger with Tuning Support via Powergate

- R300 Turbocharger with Tuning Support and Upgraded High Flow Intake

Note: Turbo inlet O.D. is 2", you can still retain your OEM Pre-turbo Intake without rubber grommet, or you can purchase our R300 Turbocharger inlet.

Warranty:

1 Year, Unlimited Mileage – Applies to the original owner from the date of purchase.

We recommend installing the turbo with genuine MINI installation hardware. You can source them at your nearest MINI dealership or order them directly from us. Please send us an email for assistance.

What makes the R300 Unit special?

We have extensively fine-tuned every hybrid turbocharger available for these vehicles. While many options might perform adequately at first, they often lead to ongoing customer support issues as mileage increases. Common concerns include, “My car was fine for the first 2000 miles, but now it isn’t boosting as it used to.” Customers frequently reach out to turbo manufacturers only to be referred back to their tuners frustrating, given that the turbo itself is brand new.

Allow us to explain why the R300 Unit is the optimal choice among hybrid turbochargers for your Mini Cooper Gen2. Most of the turbochargers on the market are built from low-quality knock-off parts, developed without a full understanding of how these engines operate, particularly in relation to closed-loop boost tuning. Many products claim impressive flow rates based on exaggerated metrics, appealing only to those with limited knowledge.

Critical to performance are the materials used, especially in the hot side alloy and the waste-gate mechanism. These engines use a twin-scroll short runner exhaust manifold designed for optimal thermal energy, allowing quick spool-up times. Unfortunately, this exposes cheap turbochargers to consistently high temperatures, particularly in high-compression models like the Cooper S. Subsequently, many of these units suffer from imbalanced flow, resulting in high back pressure and heat stress that can compromise a vehicle’s performance.

When stage 3 customers expect to run 22-23 psi, the limitations of poorly manufactured turbos become apparent. These low-quality components, not created by reputable OEM manufacturers, cannot match the longevity or reliability of genuine products, which are designed to endure for over 100,000 miles.

We grew weary of addressing these recurring issues and often found ourselves providing more aftersales support for inferior turbochargers than for our own products. Hence, we developed the R300 Unit: a reliable solution for both in-shop projects and enthusiasts seeking an OEM-like quality turbocharger that performs exceptionally without continuous issues.

With experience tuning thousands of these vehicles, we directly applied our knowledge to the R300 Unit's development. After extensive trial and error, we engineered a turbocharger that maximizes horsepower potential while reducing stress on the stock internals. The result? The R300 Unit outflows any competing hybrid turbo at 19 psi and is constructed from genuine BorgWarner components, featuring custom wheel geometry and an expertly engineered compressor housing.

This unit is designed to last as long as an OEM turbo while being highly tunable. In optimal conditions—healthy engine, quality fuel, and low boost—our R300 Unit can deliver 260 whp and 260 ft-lbs of torque. Notably, it promotes a healthier thermal environment for the OEM engine by enhancing exhaust flow without the need for aggressive tuning.

We have tailored our tuning support to accommodate all applications—stock engines, built engines, and cammed engines with additional fueling. We closely monitor the condition of the R300 Unit in our own vehicles, collecting data at intervals of 10k, 25k, and 55k miles to validate its performance and reliability. We confidently assert that no other product on the market matches its durability.

Please note that while we aim to provide the best after sales support possible, purchasing a turbocharger and tune does not automatically entitle you to ongoing support for unrelated vehicle issues. We ensure that all our products are thoroughly validated before they leave the workshop. We are committed to assisting you in diagnosing your vehicle, but we encourage you to seek professional help for complex mechanical problems.

Thank you for your understanding and cooperation.

Part Numbers for Genuine MINI Installation Parts:

- (1) Oil Feed Line: 11-65-7-534-454

- (4) Crush Washers: 07-11-9-963-151

- (2) Banjo Bolts: 07-11-9-905-176

- (1) Oil Return Line with Clamp & Bolt: 11-65-8-617-069

- (1) Down-pipe Gasket: 18-30-7-589-503

- (1) Down-pipe Clamp: 18-30-2-756-352

- (1) Oil Filter Housing Seal Kit: 11-42-8-643-758

- (1) Oil Cooler to Oil Filter Housing Seal Set: 11-42-8-643-747

- (3) Turbo to Down Pipe Nuts: 18-30-7-583-746

- (3) Turbo to Down Pipe Studs: 18-30-7-598-251

- (4) Turbo to Manifold Nuts: 11-65-7-559-557

- (4) Turbo Studs to Manifold: 11-65-7-605-340

- (1) Cooper S Turbo to Manifold Seal: 1-65-7-557-013

- (1) Cooper S Exhaust Turbo Manifold Gasket: 11-62-7-626-106

- (2) Turbo Coolant Lines Hollow Bolts: 07-11-9-905-973

- (4) Crush Washers: 07-11-9-963-201

- (10) Turbo Manifold Nuts: 11-62-7-588-104

- (10) Manifold Studs: 11-62-7-583-110

Tuning Notes:

The R300 unit is designed to deliver 260 whp and 260 ft-lbs of torque at as low as 19 psi with ignition timing calibrated for 93 octane fuel on a healthy stock engine FWD chassis, ensuring no stress on thermal efficiency or fuel capacity.

To achieve numbers beyond these figures, utilizing a built motor along with supporting hardware is essential.

Important Considerations: Final results may vary based on several factors, including:

- Fuel Grade

- Intercooler Quality

- Engine Mileage and Service Intervals

- Piston Rings Sealing

- Cylinder Head Ports (Carbon Deposits)

- High-Pressure Fuel Pump (HPFP) age and mileage

- In Tank Fuel filter condition

- Carbon buildup on intake valves and ports

- Boost Leaks

- Spark Plugs Type and Condition

Recommended Upgrades for Efficient Performance:

To enhance performance and maintain consistency, the following upgrades are recommended:

- High-Quality Intercooler

- High-Flow Downpipe

- High-Flow Panel Filter

- Spark Plugs NGK1422 Gap to 0.022"

If you need to remain emissions-compliant, you can continue to utilize the OEM catalytic converter. While there may be a slight loss in torque and peak horsepower, you can be confident in the reliability of the turbocharger.

Optimal Performance Results:

Tested on a forged N14 engine with a 10.5:1 compression ratio, utilizing stock cylinder head ports with upgraded springs and camshafts. At 19 psi, we achieved 280 whp and 260 ft-lbs of torque before reaching limitations in the stock fuel system, necessitating conservative timing due to high compression.

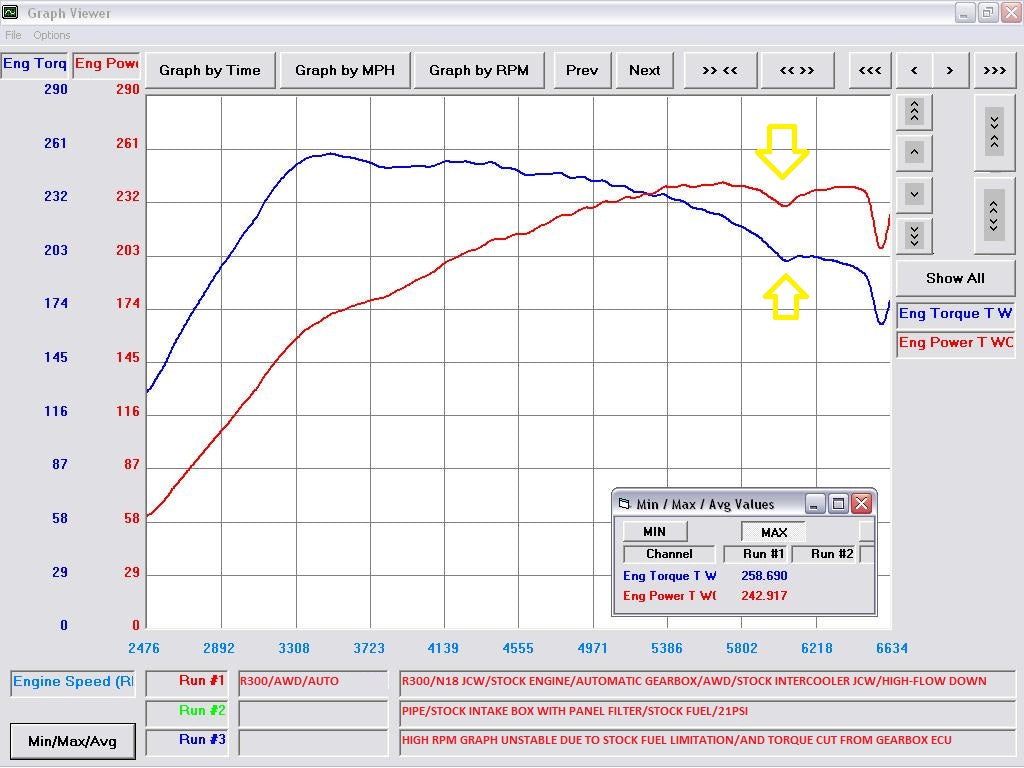

At 22 psi, we recorded 297 whp and 294 ft-lbs of torque; however, fuel limitations became evident at higher RPMs, Dyno Graphs attached.

In similar tests on the AWD R6X chassis, we observed fuel limitations at 242 awhp and 258 ft-lbs of torque. With fuel system upgrades (including port injectors, a billet intake manifold, and MPI electronics), we achieved 285 awhp and 310 ft-lbs of torque on the stock N18 engine in the AWD configuration. In a separate FWD chassis test, we reached 300 whp and 273 ft-lbs of torque with same configuration of upgrades. Note that the AWD vehicle serves as our shop vehicle, where we tested beyond safe torque limits, while the FWD vehicle was a customer car maintained at lower torque for safety.

Performance Potential:

The R300 unit can deliver up to 280 ft-lbs of torque at 3000-3200 RPM. With additional fueling support and hardware that enhances engine volumetric efficiency (VE), this unit can exceed 300 whp.

Tuning Limitations:

With the default DME firmware and OEM MAP/Boost sensors, tuning is capped at 22.5 psi (255 kPa). for purpose or retaining OEM safety controls strategies. Due to fueling limitations, there is no justification for upgrading sensors to support higher boost levels, as fueling constraints will occur before reaching 22.5 psi. To operate the R300 at boost levels exceeding 22.5 psi, a fuel system upgrade is necessary prior to upgrading the DME and sensors.

Important Considerations:

-

Vehicles used in R300 development were tested with a 5% leak down across all cylinders. We cannot assess the health of your engine or supporting hardware, but we strive to assist customers in achieving optimal results within conservative margins.

-

To prevent damage to stock engines and ensure safe operation, a proper DME tuning strategy is essential. This unit has the potential to compromise OEM connecting rods; therefore, if you intend to install this turbo on a high-mileage stock motor, proceed at your own risk. We recommend against exceeding 19-20 psi on stock engines.