DESCRIPTION

Plug and Play Intake Manifold for Mini Cooper Gen2 N14/N18 Engines

At this time, this product is made per order!

Please note, this item is only available with full MPI hardware at this time, we apologize for the inconvenience.

We supply everything required to complete a plug and play install.

Product list supplied with default purchase order:

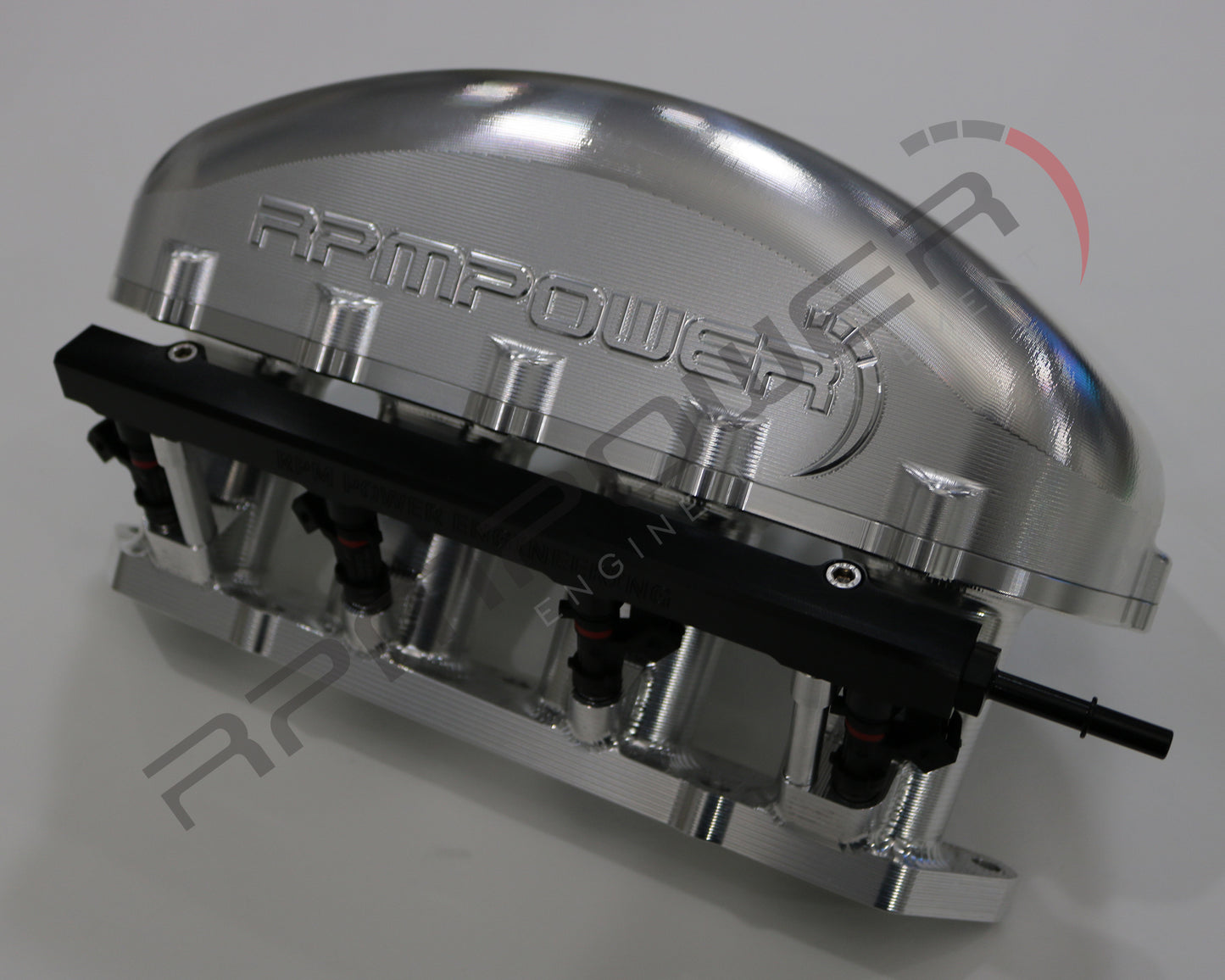

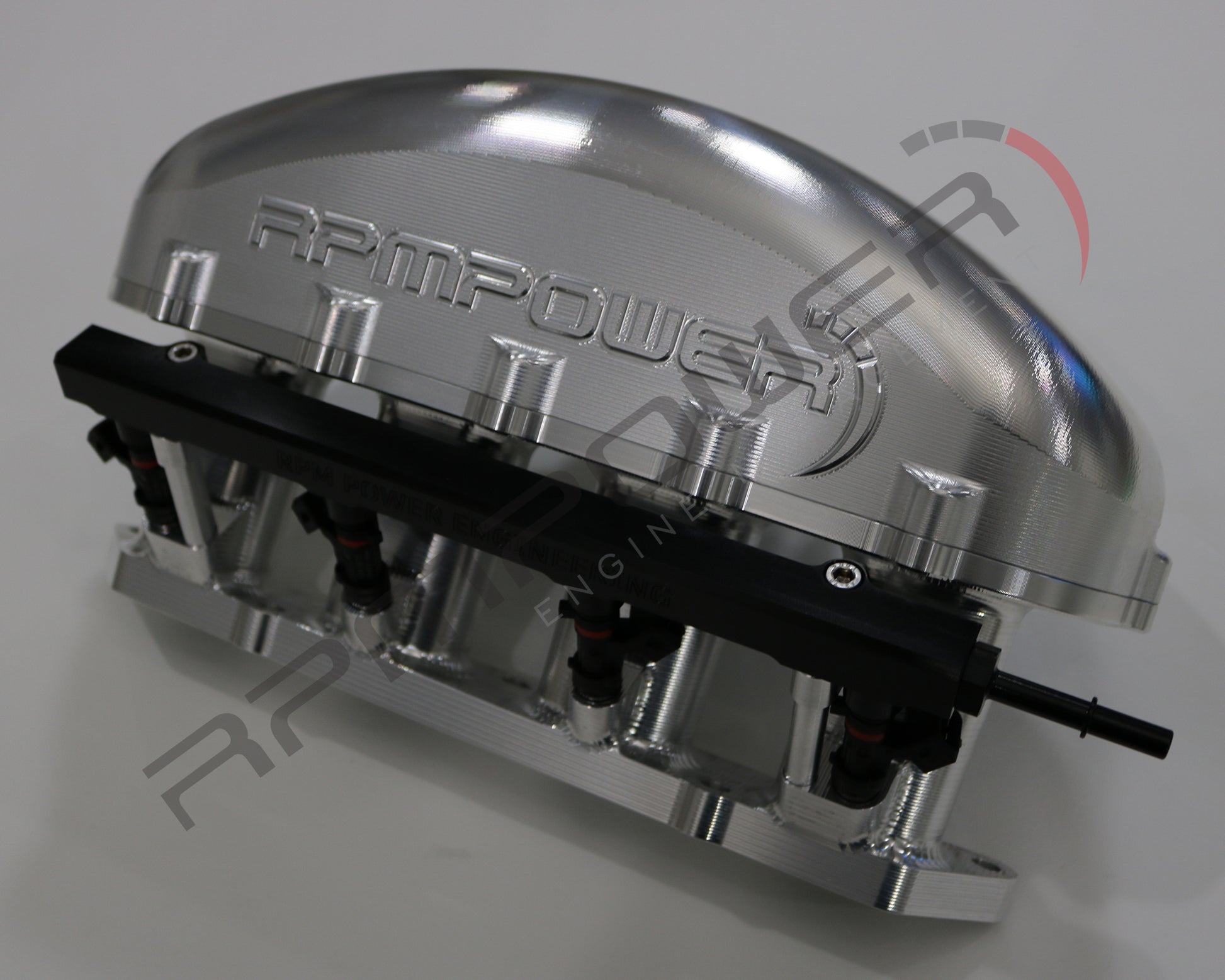

- Billet Intake Manifold (Fully machined from billet aluminum T6 6061 )

- Stainless steel install bolts for N14 or N18 cylinder head flange

- Stainless steel install bolts and washers for throttle body

- PCV Retrofit kit for N14 engine (to connect intake manifold to back of the PCV)

- Cylinder head adapter flange for N18 engine (to accommodate the difference in cylinder head shape)

- Charge Pipe to connect Throttle Body to OEM Charge pipe

- Purge Valve retrofit hardware

- Fuel injector ports capped off with 1/8npt caps (fits most water/methanol nozzles)

Product list offered at extra cost:

- Fuel rail for additional injectors, (Fully machined from billet aluminum T6 6061)

- Fuel rail brackets (with install bolts)

- EFI quick connect fitting to match OEM fuel lines

- Fuel line quick connect to OEM fuel line and HPFP (Quick Connect OEM approved EFI Fittings, fuel line rated to 250PSI, also wrapped in heat protection sleeve

- Anodizing in various colors (this will delay delivery time from the date when order was placed, approximately two weeks turn around)

- Plug and Play Electronics to support additional port injectors and external boost control (Must be used with our DME Calibration to work as developed)

Please note, after installing this product, OEM cold air intake or any other intake upgrades alike OEM style, will no longer fit. To support the fitment change, we offer the R400 Velocity Stack Intake.

Product development insights:

This product is the first product of its kind that was offered to Mini R56/6X community. Designed for the N14B16C/N18B16C engines. The engineering behind this unit features countless hours and challenges that pursuit enhanced performance over OEM intake manifold, additional ports for fuel injectors and lifetime quality. Need of this product was to satisfy support for our R400 Turbokit to its full potential with larger plenum capacity and needed fueling support over factory limits.

OEM Intake Manifold may not impress you visually as it’s made out of plastic, and it has a very small plenum size. It will eventually crack depending on its age and boost level it is exposed to, however if you try to surpass its functionality, you will face the fact that BMW/Peugeot Engineers designed a very functional unit.

Our intake development featured multiple runners and plenum designs, each design was tested in CFD software. The goal behind this development was to achieve performance gains thru the entire powerband without adding any turbo-lag to the powerband. Keep in mind, we are trying to improve the airflow on a small 1.6-liter engine, where volumetric efficiency plays a major role.

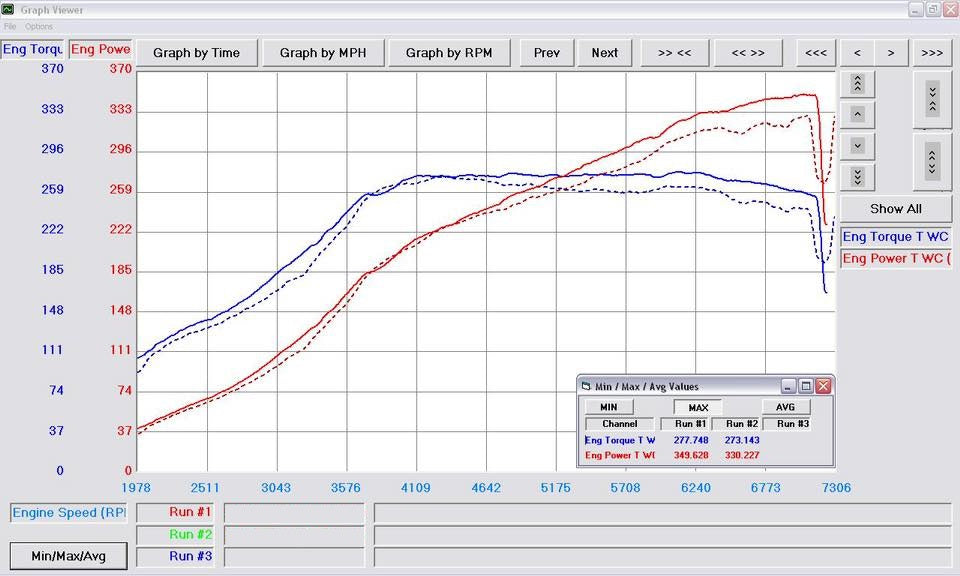

In factory form these engines have a snappy response. That offers an appreciable driving profile for a vehicle that is driven daily but also used on the racetrack. With product knowledge in mind, N14 motor with a built cylinder head will rev to 7500-8000rpm depending on configuration, and N18 motor with built cylinder head will only rev to 7000rpm due to a complex valvetronic system(at this time at list). When paired with a full frame turbo-system, size dependent, in best case scenario we want to be in full targeted torque at around 3600-4200rpm with a responsive torque ramp, that leaves us with a 4000rpm power band in the best-case scenario. Our goal was to feed more air into the engine to fulfill this rpm range. After multiple dyno sessions and tuning trials, we managed to tailor the final design and attain our end goal needs. While this development was mainly intended to support Full Frame Turbokit, we also tested it with the factory JCW Turbo, Upgraded Hybrid Turbo, R300 Turbo, and we obtained similar results, every application showed gains across entire rpm range and no low end rpm compromise.

Please note, Intake Manifold Development went along with one of the most advanced engine works that we had here at RPM Power Workshop, closed deck engine setup paired to fully built cylinder head, featuring CNC ported intake and exhaust runners, dimpled CNC port at intake runner, corrected combustion chamber volume, upgraded valves, springs, and Catcams Camshafts. Intake Manifold validated itself to support well over 600hp while showing the widest power band we have seen on these engines!

Besides functionality, this product faced challenging steps in achieving the best fitment into a tight engine bay. Cylinder head flange was perfected to use OEM gaskets, even simple things had to validate fewer steps. OEM unit is made from plastic and doesn’t bite as hard on the gasket, where on the aluminum flange after first trial, gaskets were found damaged and cut. We had to fine correct the design to accommodate gasket fitment without being cut or cracked after install. Manifold flange also features guide pins to ensure a perfect runner alignment to cylinder head ports. Throttle gasket channel was also designed to be used with OEM gasket. This assures OEM Quality and longevity but also easy servicing access to any MINI parts supplier in the world.

Please note, Intake Manifold Injector ports exits feature 1/8npt threads that can be capped if not used but also offers option to fit port injection for Water Methanol nozzles with 1/8npt nozzle threads.

We do not recommend using this intake manifold on a vehicle with an upgraded turbocharger while limited to a stock fuel system. While supplying more air to the engine, it will limit the fuel system supply earlier than expected. We recommend supporting this application with as minimum as 50/50 water methanol system with 125cc nozzle per runner thru a solenoid that will support up to 300whp without adding too much complexity to the system. If used with Full Frame Turbocharger, nozzle size needs to be tailored per application, and if the user decides to use 100% methanol as fuel, braided lines and AN fittings is a must as well proper ecu management to allow precise fuel tuning.

Please view the attached pictures for product details and for dyno chart from product end test, validated performance increase over OEM unit after successful development. Test completed with R400 Turbocharger kit on the smallest trim, 21psi boost pressure and 600cc methanol nozzle before throttle body, no connected port injection yet!

Manufactured in Canada, with imported materials.